Frame:

The frame is made of thick steel sheets that are welded together and then heated to remove any stress. It is designed to be very strong, even under heavy loads.

Drive:

The drive system uses a single gear to transmit power from the motor to the main shaft. The main shaft is supported at three points, which makes it very sturdy and prevents it from bending. The gears are enclosed and run in oil, which makes them quiet and smooth.

Eccentric Shaft:

This shaft is made of forged carbon steel and is inspected and tested before machining. It is ground to a very smooth finish. The bearings are made of heavy-walled nickel phosphorous bronze and are hand-scrapped for precision.

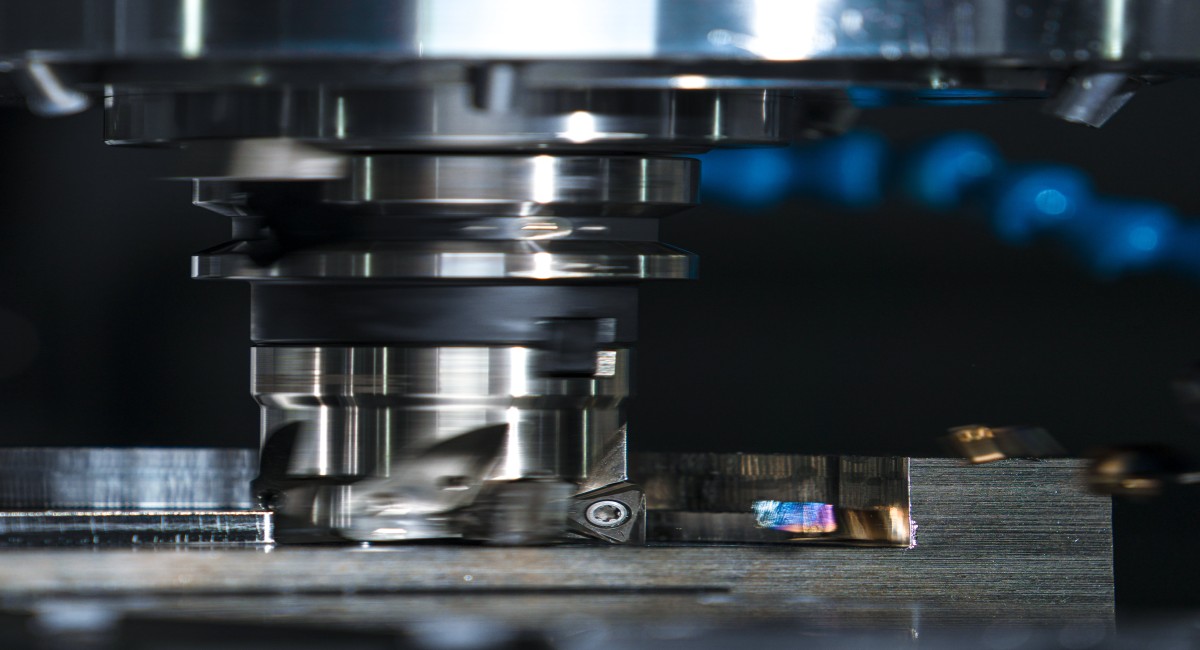

Slide:

The slide is made of graded cast iron and runs on six long gibs. The gibs have replaceable liners, which makes it easy to adjust the clearance. The large slide provides a wide area for the die and the long gibs provide a high degree of centering and rigidity.

Electrical Controls:

Electrical Controls: The press has a dual solenoid valve that prevents faulty operation. It also has a "top stop" to stop the press at the top of its stroke, a two-hand engagement device, an emergency stop, and a lockable selector switch to choose between single, inching, and continuous operation. The electrical equipment meets all the latest safety standards.

Slide Counterbalance:

A pneumatic counterbalance helps to support the weight of the slide and tooling. This makes it easier to adjust the bearings, smooths the movement of the slide, and improves braking.

Pneumatic Clutch And Brake:

The single disc clutch is safe and fast operating, self-ventilating, and high-performance. It provides a continuous stroke and does not require adjustment to correct wear.

Lubrication:

A central pump with a capillary distributive system automatically lubricates all moving parts.